-

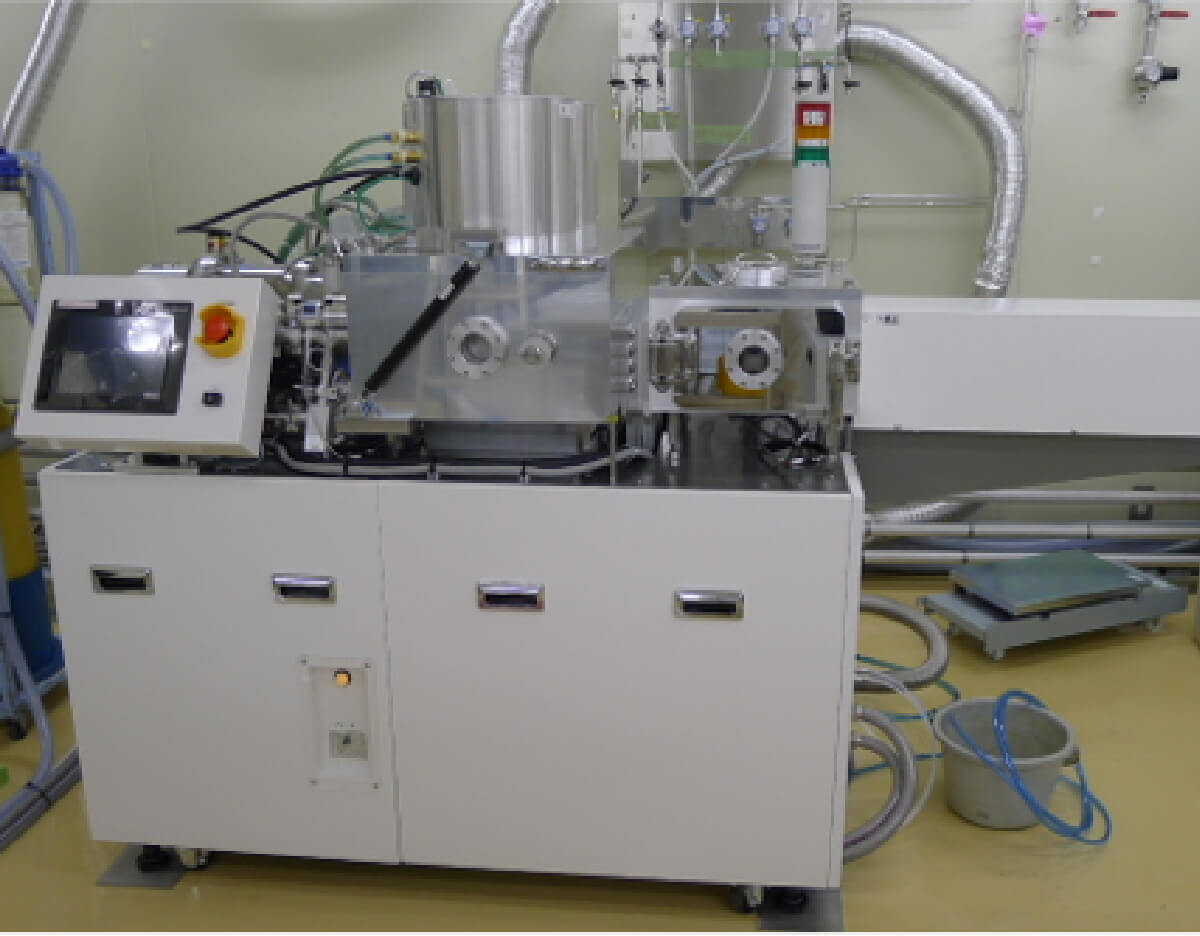

Cluster Type High-temperature Sputtering System

Features

- Our original sputtering cathode

- Moving magnets for full erosion

- Our original heating mechanism of rapid temperature-raising/lowering for a substrate temperature 900℃.

- High-speed and stable reactive sputtering film deposition is possible by plasma emission analysis and feedback control.

- Low temperature process such as liftoff ,etc. is also available

- Applicable for tray transportation

- Combinations such as CVD room, vapor deposition room, plasma cleaning room, etc. are also available.

Applications

- Semiconductor

- MEMS

- Electronic components

- Optical components

- Vehicle components

Specification

Sputtring Cathode φ12 inch maximum Sputtring Power Supply Magnetron Method

Target shutterSpatter Power Supply RF or DC Process Gas Ar, O2, N2, etc. Substrate Stage Substrate heating: 700 ° C (substrate surface)

Rotation: 20rpm maximumVacuum Exhaust Type 1:TMP+DP

Type 2:CP+DPPressure Control APC Control Operation Control: PLC

Operation: Touch panel or PCData Logging External memory or PC Substrate Transfer Vacuum transfer robot Option Substrate bias(RF or DC)

Substrate cooling (low temperature film deposition)

Moving magnet

Cathode for magnetic material target

Plasma emission monitor

Tray transportation

Q-MASS and more -

Multiple Sputtering System

Features

- Our original sputtering cathode

- 3-Axis mechanism (elevation, revolution and rotation) is equipped on the substrate stage for film thickness uniformity

- Our original heating mechanism of rapid temperature-raising/lowering for a substrate temperature 900℃.

- Up to 4 sputtering cathodes can be equipped for a multilayer film of metallic films, oxide films and more.

- Combinations such as CVD room, vapor deposition room, plasma cleaning room, etc. are also available.

Applications

- Semiconductor

- MEMS

- Electronic components

- Optical components

- Vehicle components

Specification

Sputtring Cathode φ12 inch maximum Sputtring Power Supply Magnetron method

Target shutterSpatter Power Supply RF or DC Process Gas Ar, O2, N2, etc. Substrate Stage Substrate heating: 700 ° C (substrate surface)

Rotation: 30 rpm

Revolution: 10 rpm

Elevation: 50mmstVacuum Exhaust Type 1:TMP+DP

Type 2:CP+DPPressure Control APC Control Operation Control: PLC

Operation: Touch panel or PCData Logging External memory or PC Substrate Transfer Vacuum transfer robot Option Substrate bias(RF or DC)

Substrate cooling (low temperature film

Moving magnet

Cathode for magnetic material target

Plasma emission monitor

Tray transportation -

Batch Type 3D Sputtering System

Features

- Our original sputtering cathode

-

Deposition stage is equipped with a 4-axis mechanism (elevation, revolution, rotation, tilt).

Achieves high coverage for three-dimensional objects. - Up to 3 sputtering cathodes can be equipped for a multilayer film of metallic films, oxide films and more.

Applications

- MEMS

- Electronic components

- Optical components

- Vehicle components

Specification

Substrate Size φ5 inchx40mm high maximum

Please contact us as it depends on the shape, size, material and more.Sputtring Cathode Magnetron method

Target shutterSputtring Power Supply RF or DC Process Gas Ar, O2, N2, etc. Work Stage Heating temperature: 500 ° C (substate surface)

Rotation: 30 rpm

Revolution: 10 rpm

Elevation: 40mmst

Tilt: ±30°

Substrate bias (RF or DC)Vacuum Exhaust TMP + RP Pressure Control APC Control Operation Control: PLC

Operation: Touch panel or PCData Logging External memory or PC Work mounting Top lid that elevates, turns, opens and shuts Option Substrate cooling (low temperature film deposition)

Moving magnet

Cathode for magnetic material target

Dry pump

Plasma emission monitor

Q-MASS and more -

Ultra High Temperature Sputtering System for Thin Film MEMS

-

Batch Type Sputtering System for Thin Film MEMS

-

IBS System for Research and Development

-

Multiple Sputtering RTA Composite System

* Operating at a coin laundry in Tohoku University

-

Sputtering System with GB For OLED

-

Load-lock Type Dual Cathode Sputtering System

-

Batch Type Triple Cathode Sputtering System for Research and Development