Custom-made Products

▼Customization Examples

■Electrode and Magnet Design

① Sputtering Electrode Design for 3D Objects

② Sputtering Electrode Design for Powder Coating

■Special Work Stage Specifications

① Heating Temperature: Room Temperature to 1000°C

② Rotation, Revolution, Tilt Mechanism, and Bias Mechanism

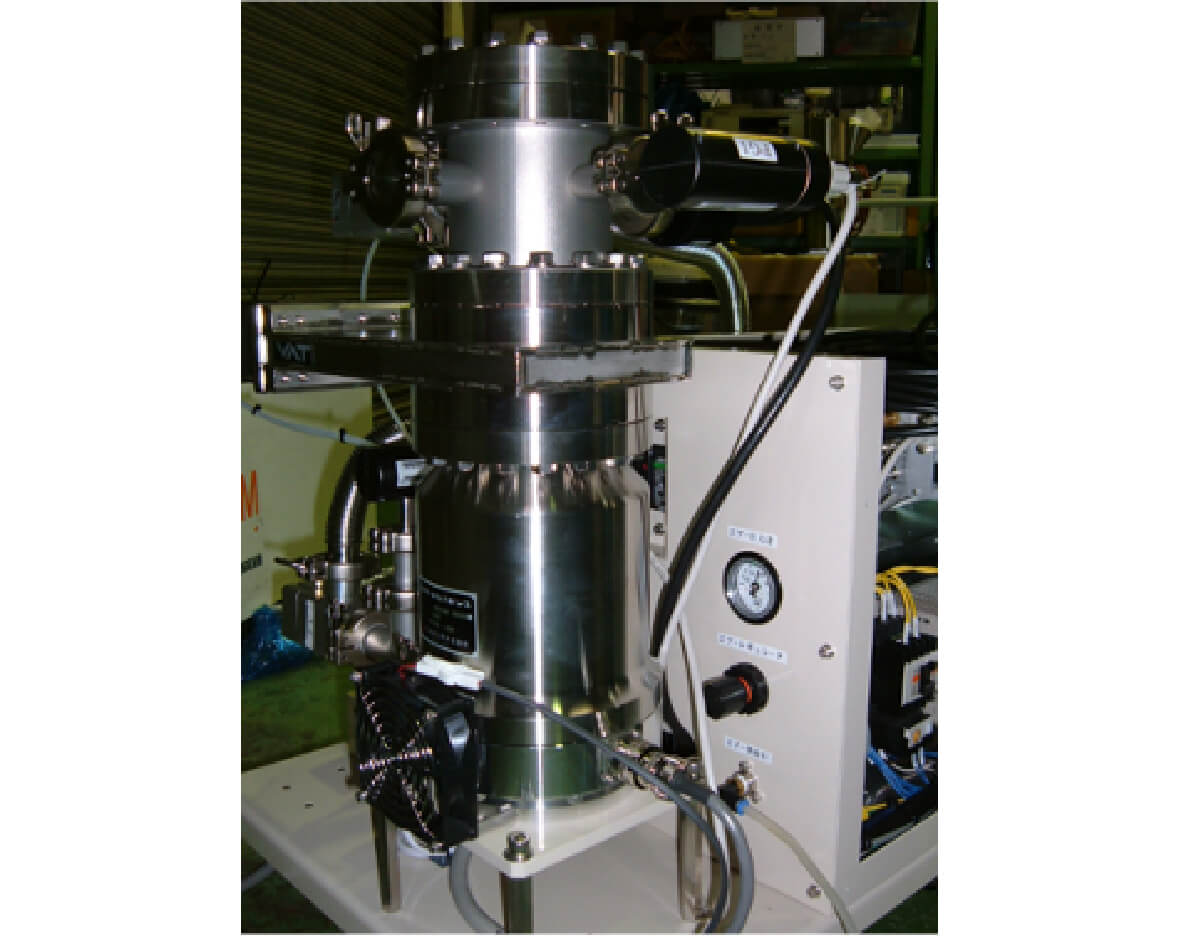

③ PZT Single Crystal Thin Film Sputtering System Design

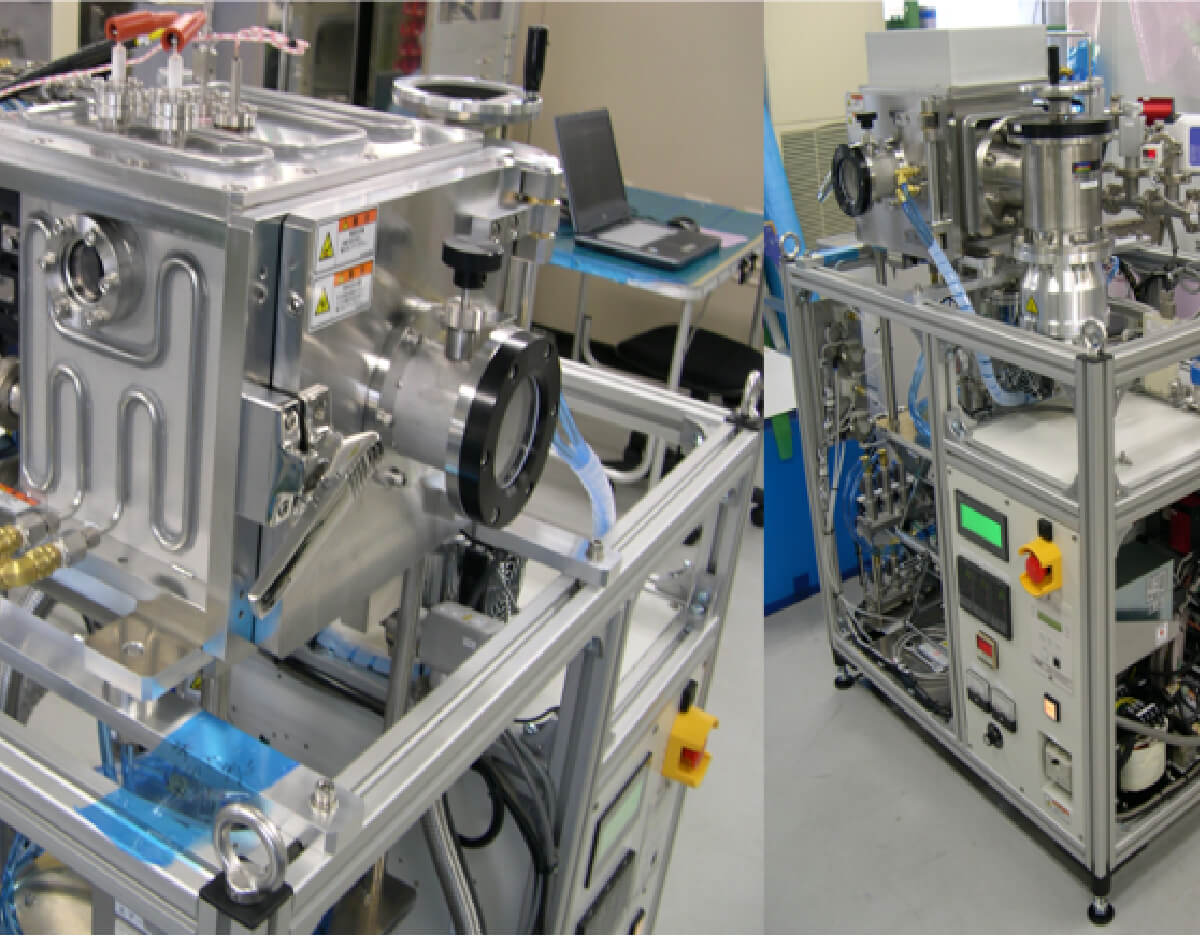

■Multi-Chamber System for Different Film Deposition Methods

① Multi-Chamber System Equipped with a Sputtering Chamber and a CVD Chamber

② Multi-Chamber System Combining Different Film Deposition Processes, Including Sputtering, CVD, and Vapor Deposition

-

Annealing System for Research and Development

-

Low Temperature Glow Plasma Experimental System

-

Cryogenic Film Deposition System

-

R to R Plasma Processing System for 390 mm Wide Film

-

TMP+RP Exhaust Set

-

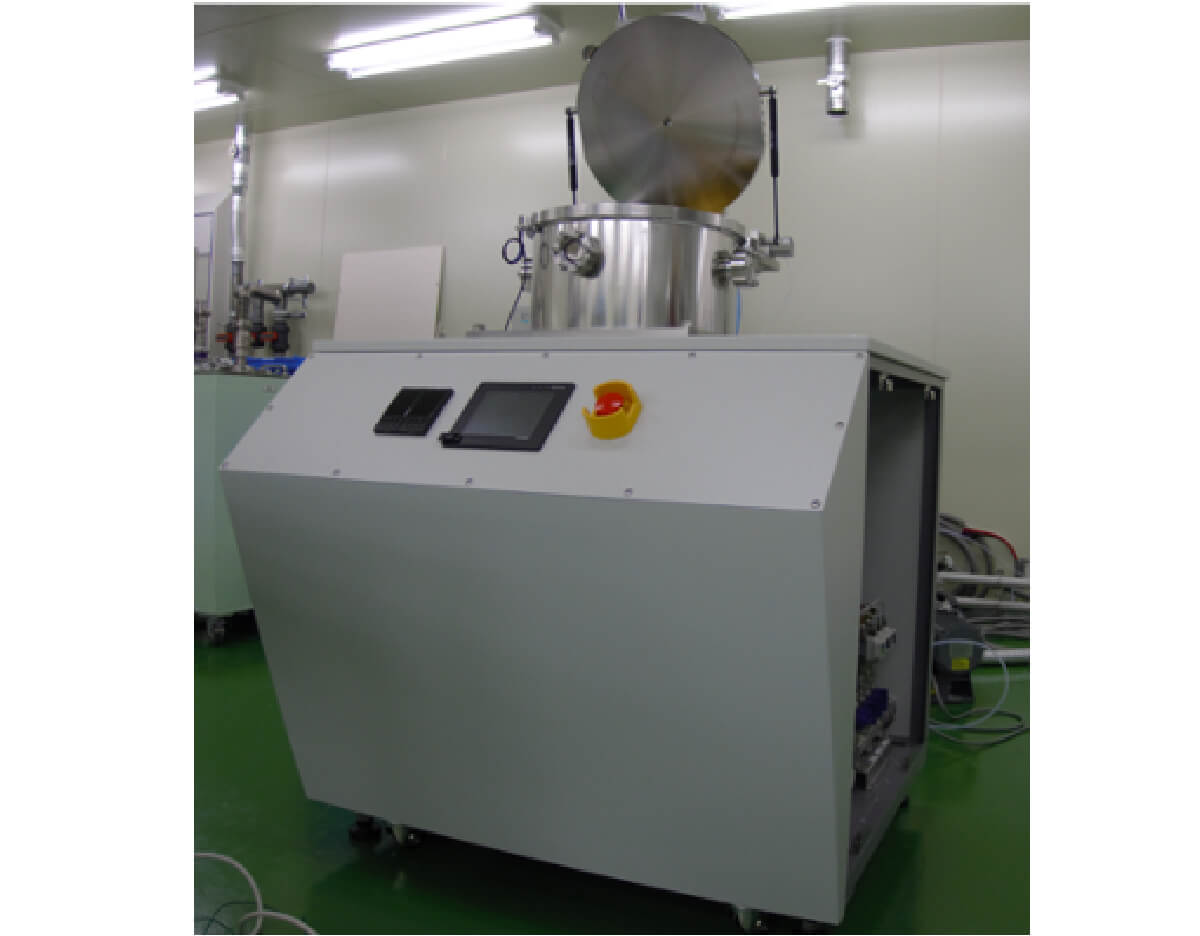

Batch Type Plasma Processing System

-

Ultra High Vacuum Chamber for Analysis

-

HW System Surface Modifier (CAT)

-

Load Lock Type Plasma CVD System (our demo machine)