Spinner

Spin Cleaning Device (Single Wafer)

We are a manufacturer mainly focusing on wafer cleaning device / etching device /

spin dryer etc. / and semiconductor manufacturing device.

We are a company that can manufacture according to your desires, whether small device for research, or automatic device for mass production purposes.

We also develop and manufacture cleaning device for LCD, PDP, organic EL, FED, LED and more with our technology.

We are able to offer at a low price since all products are manufactured within the company.

Please feel free to contact us regarding maintenance for our's and also other companies' products.

-

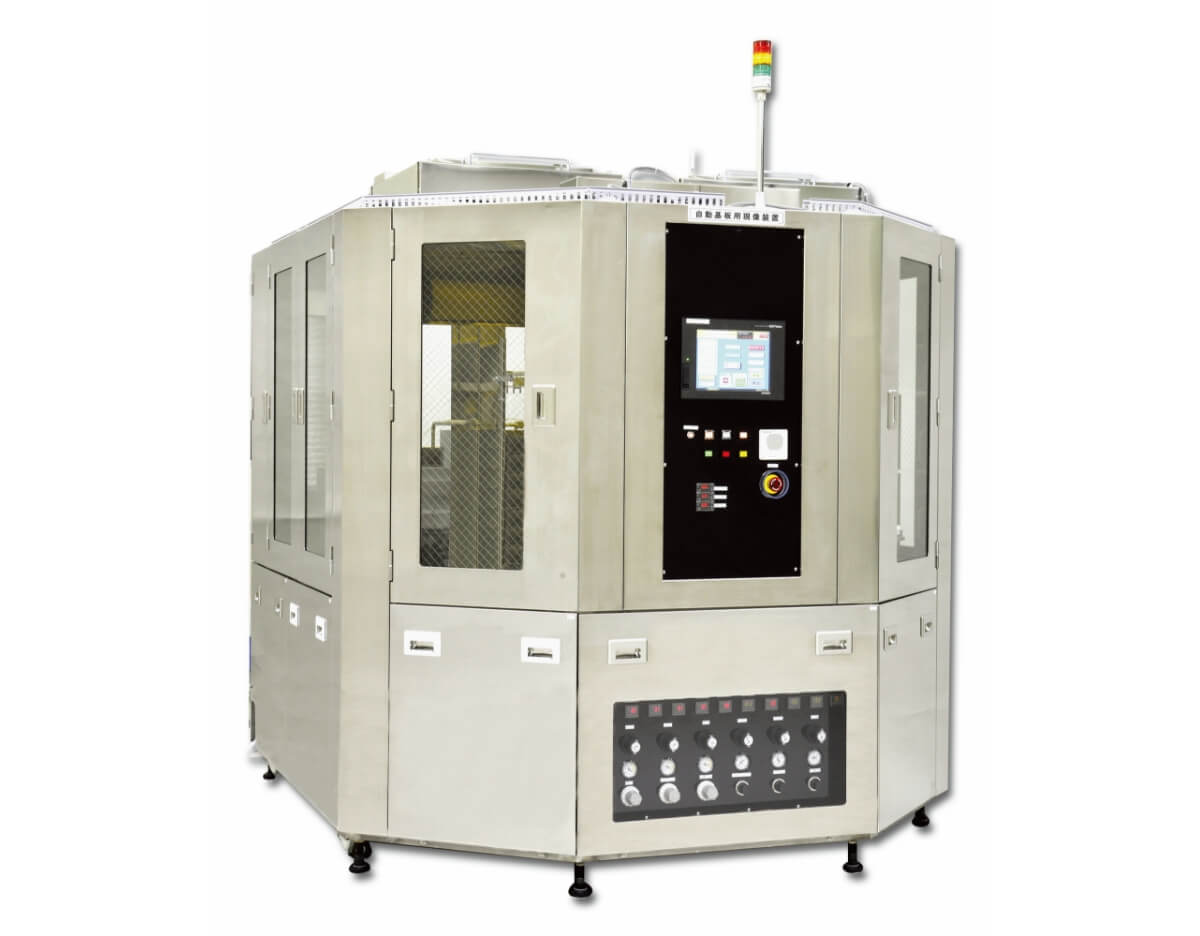

Automatic Developer

The single-wafer photoresist developer uniformly sprays a temperature-controlled developer onto the wafer for high-precision development.

Specification

Automatic Developer ~φ300m / m HEPA or ULPA Optional Function Developing temperature control/ spray/ paddle Others Hot plate/ cool plate/ rinse/ dry Rotation Speed Standard 3000rpm maximum IN/OUT Cassette to cassette/ Foup and more Conveyor Articulated robot

Holding method=Edge clamp/ electrostatic/ Bernoulli etc. -

Automatic Resist Coater

Applies resist evenly using our unique coating technology.

Coating under reduced pressure is available as an option.

Specification

Wafer Size ~φ300m/m HEPA or ULPA Optional Function Dispenser/ force feeding tank/ cup cleaning Baking Hot plate/ vacuum chamber Number of Rotations Standard 5000rpm maximum IN/OUT Cassette to cassette / Foup and more Conveyor Articulated robot

Holding method = edge clamp/ electrostatic/ Bernoulli and more -

Spray Developer

The system is a spin-type spray developer that develops, rinses, and dries automatically or manually.

It can process several wafers at the same time.

Specification

Wafer Size ~φ300m/m HEPA or ULPA Optional Function Developing liquid temperature control/ spray/ paddle Others Rinse/ dry Rotation Speed Standard 3000rpm maximum IN/OUT Manual Number of processing sheets Negotiable -

Desktop Type Manual Spin Coater

¥A desktop manual coater corresponding to a 300mm size glass substrate.

Process conditions are set on the touch panel of the operation panel. A current mode is displayed on the touch panel during each processing mode.

Specification

External Dimensions W420×D500×H335 Motor 600W AC Servo Motor 200V

15A transformer for 100V (optional)Number of Rotations 0 to 3000rpm (5000rpm maximum is optional) Number of Rotations Display Digital display Rotation Accuracy ±1rpm Number of Programs 10 programs 50 steps Sample Stand Vacuum suction -50Kpa (vacuum pump is optional) Inner Cup Φ270 aluminum scraping, surface treatment Outer Cup SUS304 φ360 drawing