-

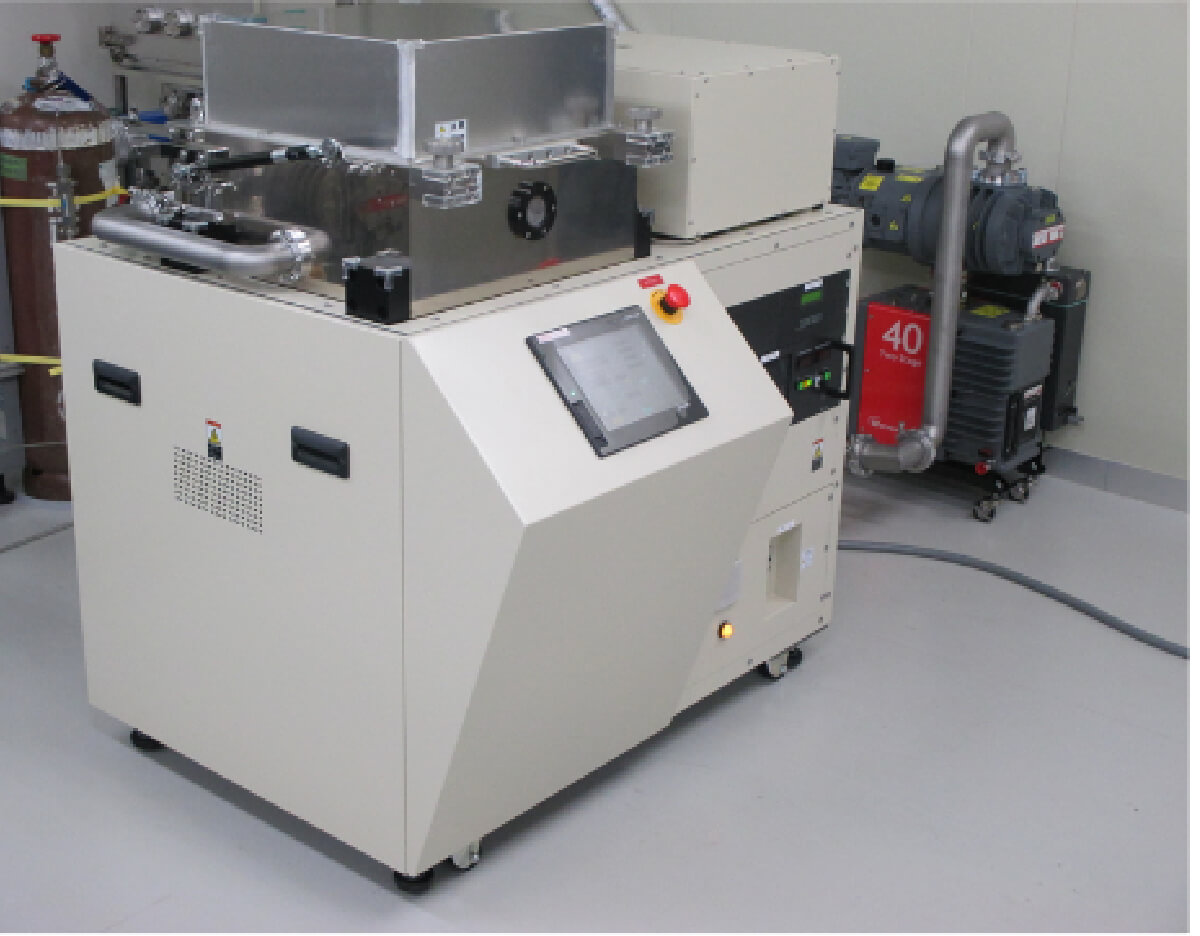

SiO2/SiN PE-CVD System for 300mm

Features

- Low stress, high hardness and high insulation by dual frequency

- Superior film thickness uniformity and reproducibility

- Reduction of metal contamination by special surface treatment

- Significant particle reduction and improved productivity with radical plasma cleaning system

- Controls wide range of film characteristic

- Plenty of accumulated data

- Applicable for tray transportation

Applications

- Semiconductor

- MEMS

- Organic EL

- Solar Cell

- Electronic Components

- Optical Components

Specificationss

Substrate Size φ12 inch maximum Process SiH4 : SiO2, SiNx, SiON, a-Si

TEOS/ TMOS : SiO2Plasma Source CCP type Substrate Heating Temperature 300 ° C maximum (substrate surface) Vacuum Exhaust Low vacuum process: MBP+DP

High vacuum process: TMP+DPPressure Control Auto pressure control Control Operation Control: PLC

Operation: Touch panel or PCData Logging External memory or PC Substrate Transfer Vacuum transfer robot Option Plasma Emission monitor

Exhaust gas treatment system -

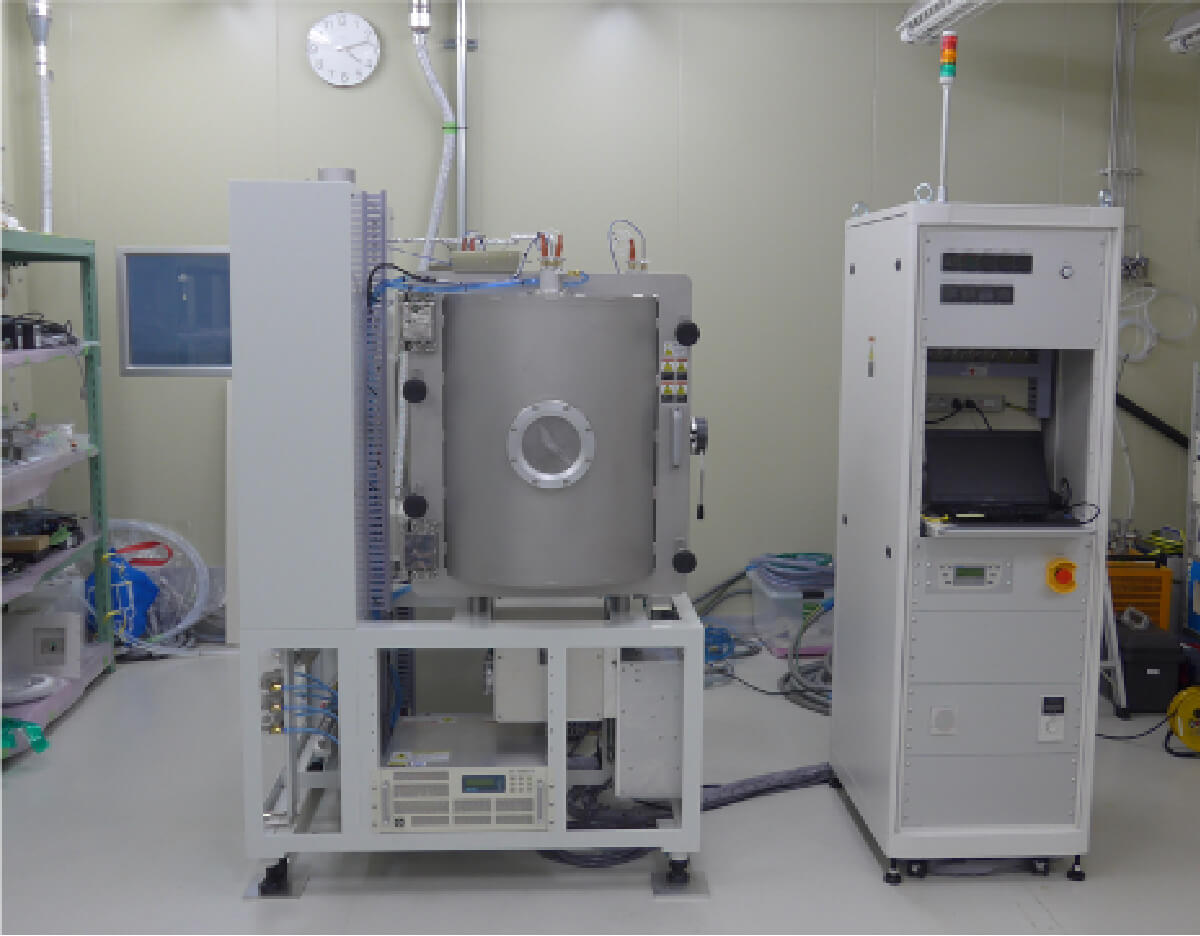

Diamond-Like Carbon (DLC) Coating System

Features

- Substrate heating source can be selected from water cooled type and heated type

- Ion source can be selected from RF plasma CVD method and ionized deposition method

- Substrate stage can be selected from water cooled type and heated type

- Superior film thickness uniformity and reproducibility

- Processable for various substrate materials

- Controls wide range of film characteristic

- Plenty of accumulated data

- Applicable for tray transportation

Applications

- Semiconductor

- Electronic components

- Optical components

- Vehicle components

- Medical components

Specificationss

Substrate Size Round φ12 inch maximum

Square 310mm x 375mm maximumProcess Gas DLC:Liquid・Gas

Fluoride DLC: LiquidSelf Cleaning Gas O2, Ar, etc. Substrate Heating Temperature 300 ° C maximum (substrate surface) Vacuum Exhaust Low vacuum process: MBP+DP

High vacuum process: TMP+DPPressure Control APC Control Operation Control: PLC

Operation: Touch panel or PCData Logging External memory or PC Substrate Transfer Vacuum transfer robot Option Plasma Emission monitor

Exhaust gas treatment system -

Carbon Nanotube Growth System

Features

- Fully automated process

- Substrate plasma cleaning system

- Superior substrate temperature uniformity and gas flow method

- Superior film thickness uniformity and reproducibility

- Plenty of accumulated data

Applications

- Energy related

- Material related

- Bio related

- Nano technology related

- Electronics related

Specificationss

Process Gas φ12 inch maximum CNT Syngas CH system, H2 Substrate Heating Temperature 800 ° C maximum (substrate surface) Vacuum exhaust RP Pressure Control APC Control Operation Control: PLC

Operation: Touch panel or PCData Logging External memory or PC Option Substrate automatic transfer system

Gas detector

Cylinder cabinet and more -

3D CVD System

Features

- Chamber volume 1m3

- Original plasma control method

- Multistage mass processing

- Simple structure with high versatility

- Processable for various product materials

- Controls wide range of film characteristic

- Plenty of accumulated data

Applications

- Sliding parts

- Sliding components

- Adornments

- Vehicle components

- Machine components

Specificationss

Work Size Please contact us as it depends on the shape, size and material. Chamber Size 1m×1m×1m Film Types DLC, Fluorine DLC, SiOx, SiON Self Cleaning Gas O2, Ar, etc Vacuum Exhaust MBP+RP Pressure Control APC Control Operation Control: PLC

Operation: Touch panel or PCData Logging External memory or PC Option Dedicated jig

Gas detector

Cylinder cabinet and more -

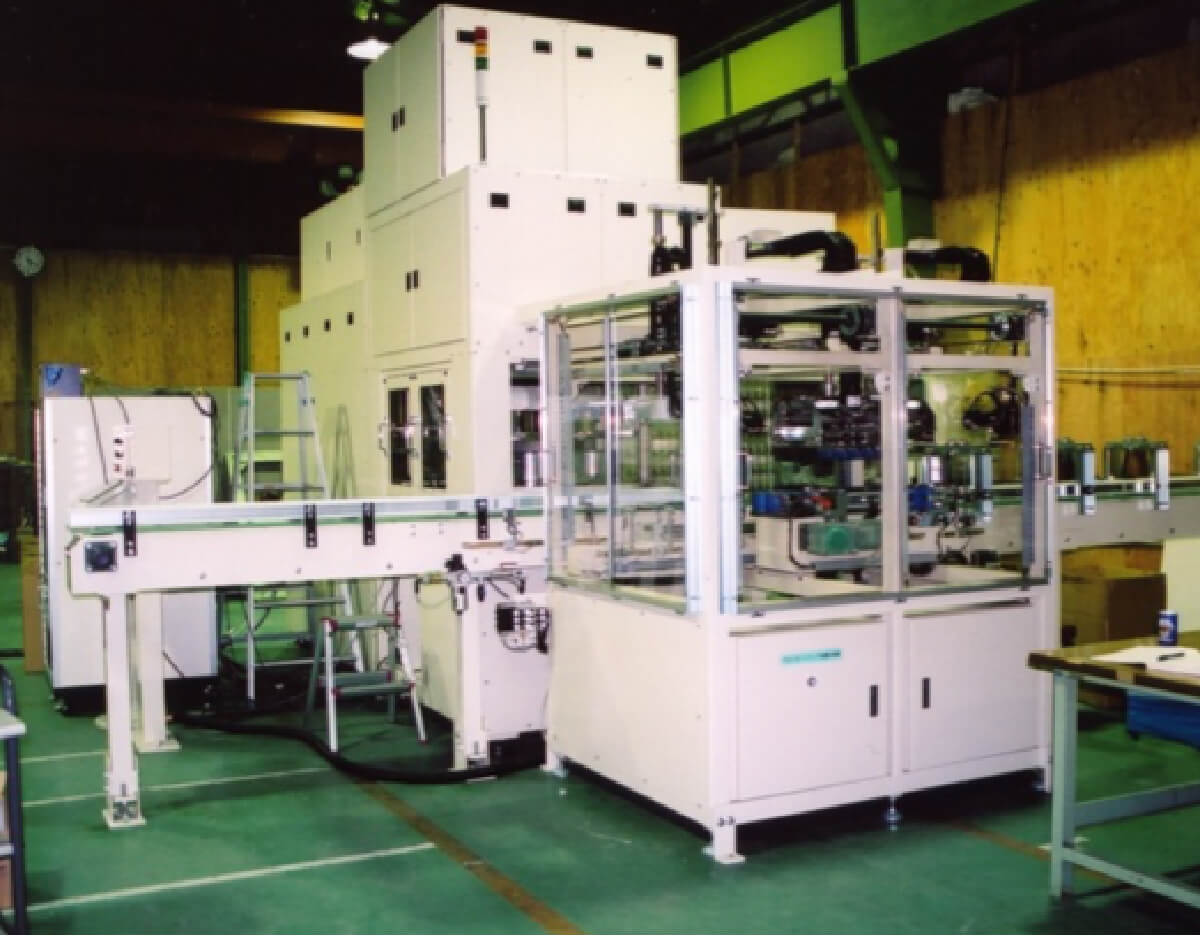

Plasma CVD System for Plastic (Polyethylene Terephthalate) bottles

Overview

Widely used for Diamond-Like Carbon (DLC) coating inside a plastic (Polyethylene Terephthate) bottle by our highly skilled plasma CVD technologies.

By applying a submicron order of DLC thin film coating to an inner surface of plastic bottles, it prevents flavor degradation due to oxidation and elution of carbonic acid components.

It also lowers distribution costs by reducing the weight of the bottle.Applications

- We can suggest various equipment configurations depending on the required production quantity.

- It can be coated up to 3L containers

- Contact us for bottles or containers larger than 3L.

- Contact us for resin materials other than PET resin.

- Contact us about metal materials.

-

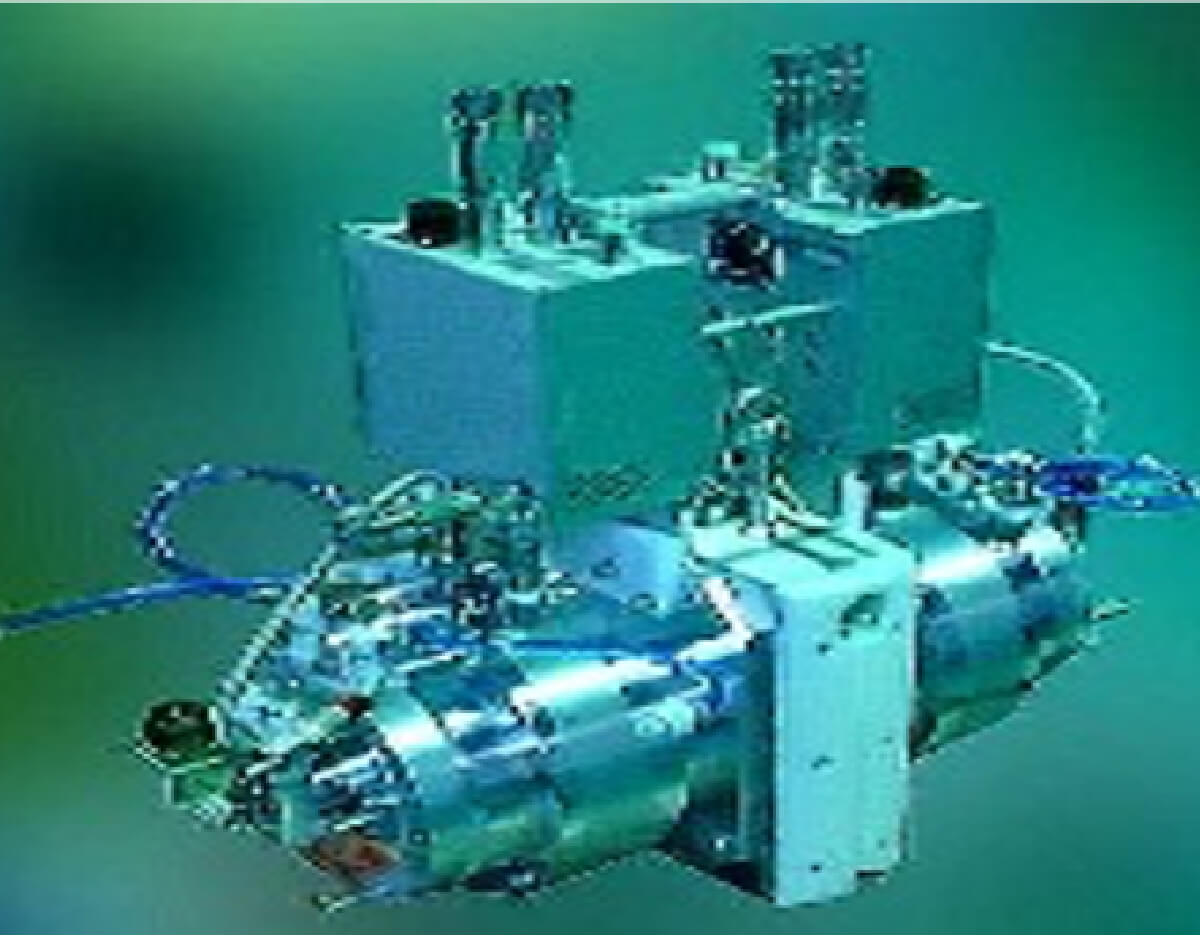

HDD Media

Double-side Ultrathin DLC Film Deposition Unit

-

HDD Head

Multi-Chamber DLC Film Deposition System

-

HDD Head

Batch Type DLC Film Deposition System

-

Load-lock Type Plasma CVD System For Research and Development

-

Plasma CVD System For Metal Containers

-

Plasma CVD System For Medical Containers

-

Plasma CVD System For Three-dimensional Objects

-

12 inch ALD System For Basic Research and Development

-

ICP Source MOCVD System

-

Plasma CVD System For Solar Cells

-

Mass Production Multi-Chamber Plasma CVD System For Glass Substrates